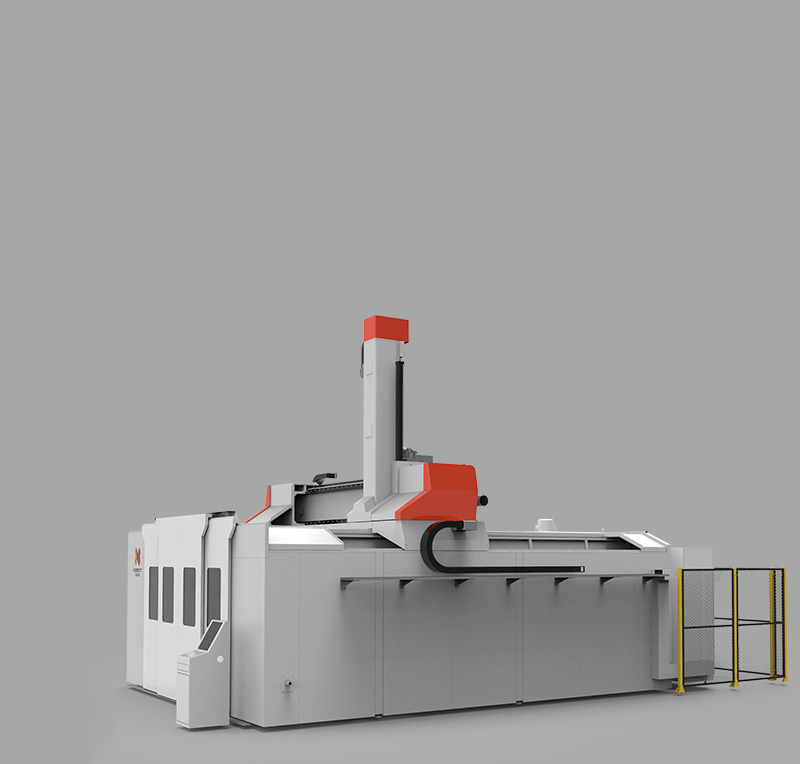

About NOBOT

Nobot Intelligent Equipment

Nobot Overview

Nobot Intelligent Equipment Group was founded in 2013 and is headquartered in Liaocheng City, Shandong Province. It is a high-tech enterprise integrating R&D, production, sales, and after-sales service. The company brings together more than 50 R&D personnel, including more than 20 professors and senior engineers.

Nobot was founded in

OUR HONORS

The company has established a complete management system and has passed the ISO9001 quality management system certification, ISO14001 environmental management system certification, and CE EU safety certification. It has also established R&D bases and operation centers in Beijing, Xi'an, Suzhou, Shenzhen, and Nagoya, Japan, ensuring seamless connection between technology, personnel, and market, and establishing a rapid response mechanism to meet customer needs.

10 Years Experience NOBOT

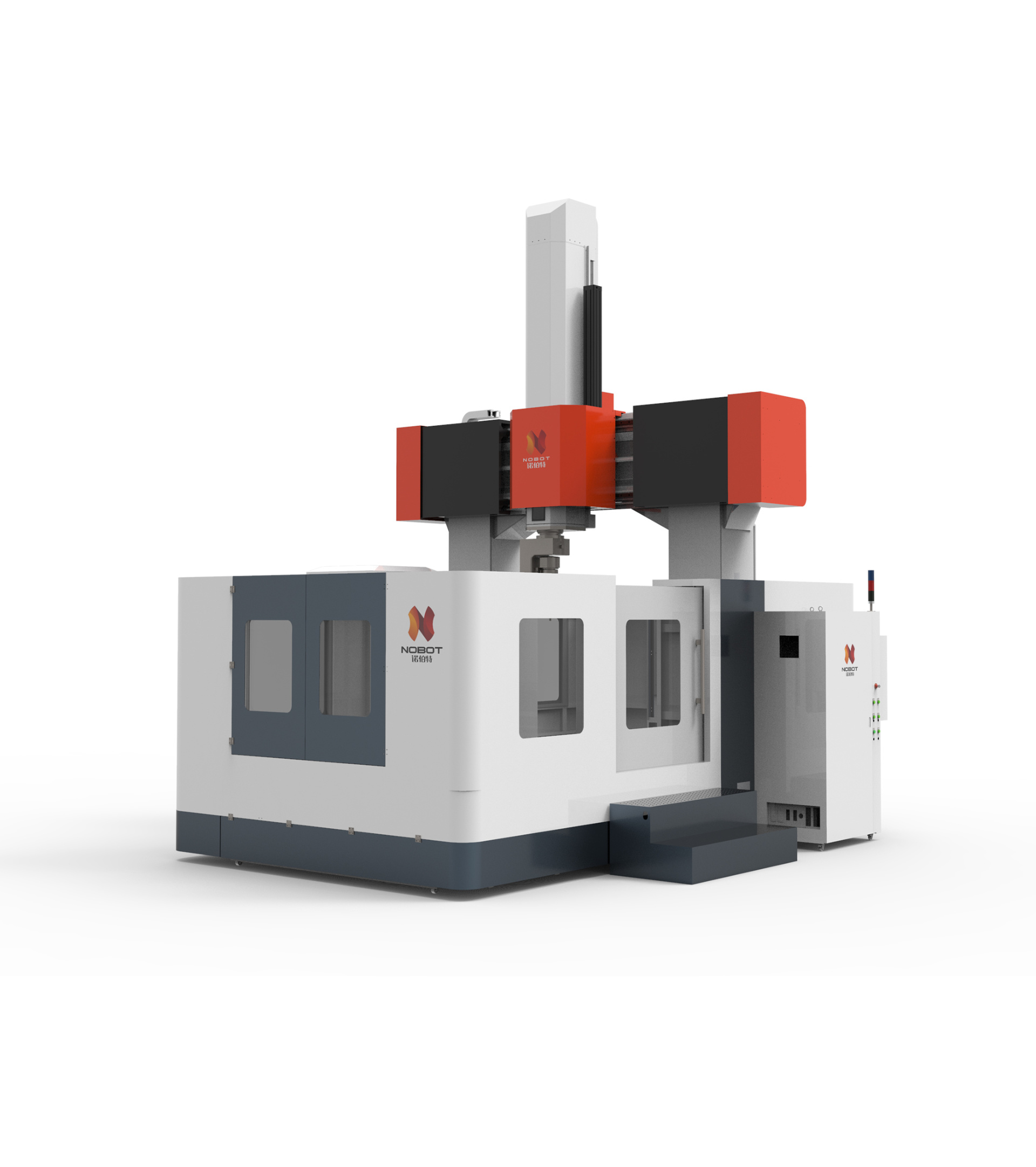

APPLICATION FIELD

and is widely used in the processing of non-metallic materials in industries such as rail transit, aerospace, automotive interiors, medical devices, and mold manufacturing, as well as in the polishing of castings such as auto parts, electrical fittings, and fire-fighting pipe fittings.

Rail Transit

Intelligent equipment achieves millimeter-level precision processing of composite materials for rail transit vehicles. Through laser scanning and adaptive cutting systems, it automatically processes lightweight materials such as carbon fiber reinforced polymers (CFRP), solving the problem of interlaminar tearing caused by traditional processing, improving the yield rate of parts by 40%, and meeting the core requirements of high-speed rail/subway carriages for high strength and low weight.

Aerospace

For complex curved non-metallic components such as PEEK heat shields for aero-engine blades and cabin interiors, intelligent equipment equipped with multi-axis articulated robotic arms performs micron-level polishing. Combined with AI visual defect detection, it eliminates the risk of stress concentration caused by manual polishing and ensures the structural stability of key components in extreme environments.

Auto Parts

For aluminum alloy die-casting burr cleaning of engine cylinder blocks, gearbox housings, etc., intelligent grinding robots equipped with force control sensors automatically identify the position of the burrs, dynamically adjust the contact pressure of 0-50N, achieve full coverage processing of deep cavity irregular structures, replace manual high-risk operations, improve the processing efficiency of single pieces by 3 times, and achieve surface consistency of Sa2.5 level.

Medical Devices

In the processing of medical-grade polymers such as surgical robot housings and orthopedic implants, intelligent equipment solves the problem of thermal degradation of medical PEEK, polylactic acid (PLA), etc., through constant temperature cooling cutting and sterile environment integration modules. The surface roughness is controlled within Ra0.8μm, meeting the mandatory standards for biocompatibility and accelerating the certification process of Class III medical devices.

Mold Manufacturing

For the processing of conformal cooling channels in precision injection molds, intelligent equipment integrates topological optimization algorithms and micro-fine electric discharge machining technology to etch φ0.3mm complex cooling channels on S136 mold steel, reducing the injection molding cycle by 25%, eliminating warping defects in products such as car lampshades and mobile phone casings, and promoting the revolution of high-gloss, spray-free molds.

Automotive Interior

Applied to the customized production of high-end automotive intelligent cockpits: The 3D laser cutting system precisely processes the leather/ultra-fiber suede interior wrapping layer, and the adaptive edge pressing technology avoids material stretching and deformation; the CNC intelligent center simultaneously completes the hollow carving of wood grain decorative panels, achieving 0.1mm-level precision in multi-material nesting processes, significantly improving the interior assembly efficiency of luxury vehicles.

More options, more choices

Contact us to get more information and quotation about product customization.

* If you have any questions, please contact us!

Contact us immediately for more possibilities!

NOBOT

Latest Blogs

What else do you need?

What else can we do for you?

Nobot adheres to the business philosophy of "integrity, dedication, innovation, and transcendence", relying on its technological advantages and actively exploring high-end technologies to strive to become a leader in the intelligent equipment industry.

2025-02-12

2025-02-12