Product Category

Contact Us

Pre-sales consultation:86-635-2932233

Fax:86-635-2945333

After-sales consultation:86-635-5086881 / 86-635-2936881

National unified service hotline:86-400-823-3356

Email: nuobote@nobot.cc

WhatsApp: 85244839434

Address: No. 1 Factory, Huanghe Road, No. 88, High-tech Zone, Liaocheng City, Shandong Province

Products

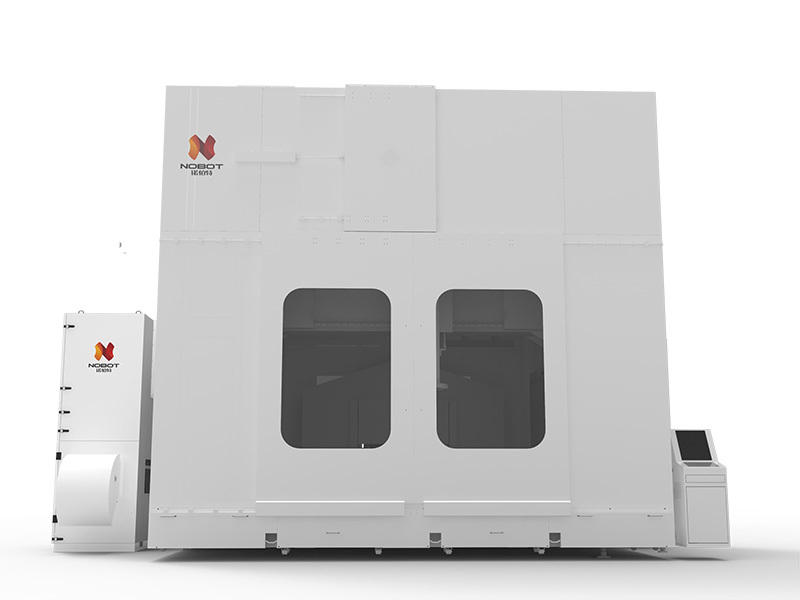

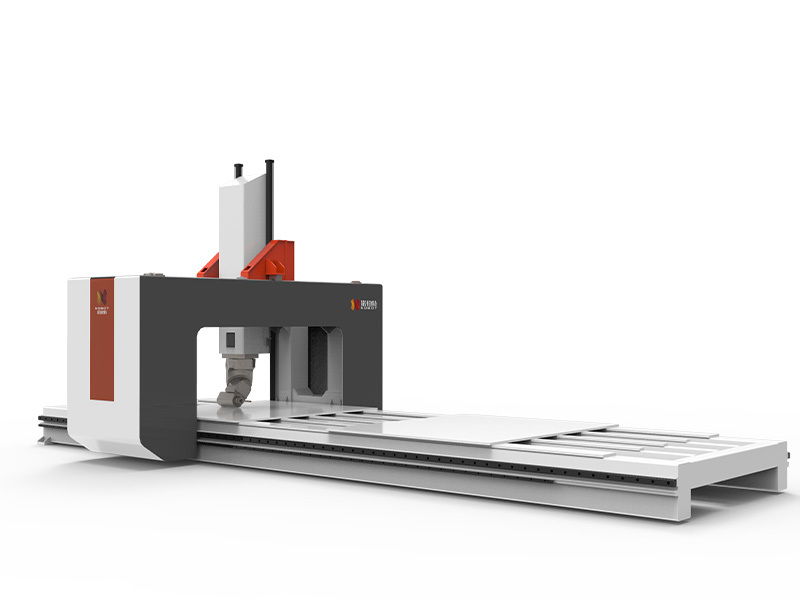

DQF series fully enclosed high-speed five-axis gantry machining center

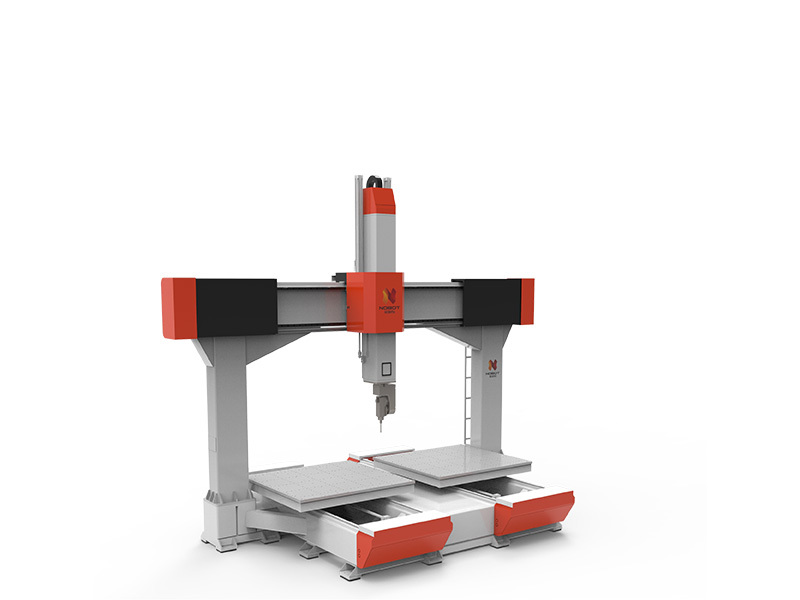

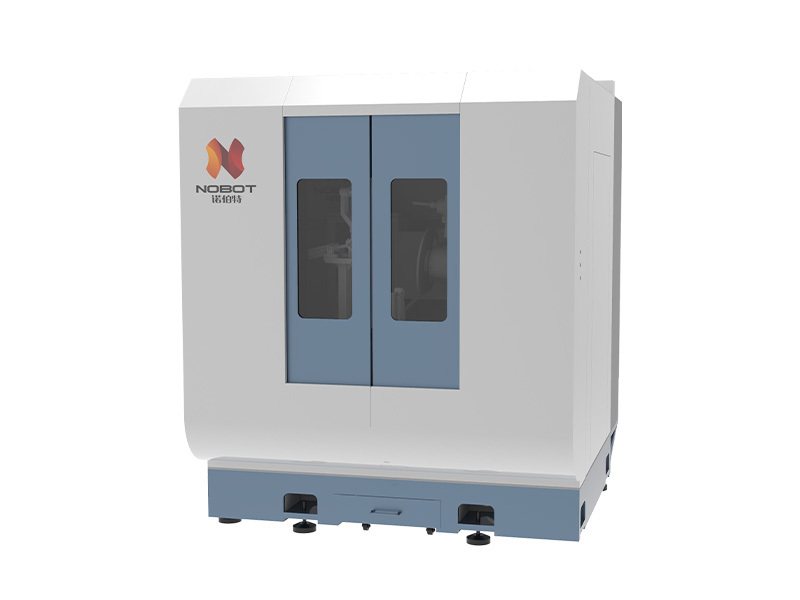

NBF series general-purpose five-axis machining center

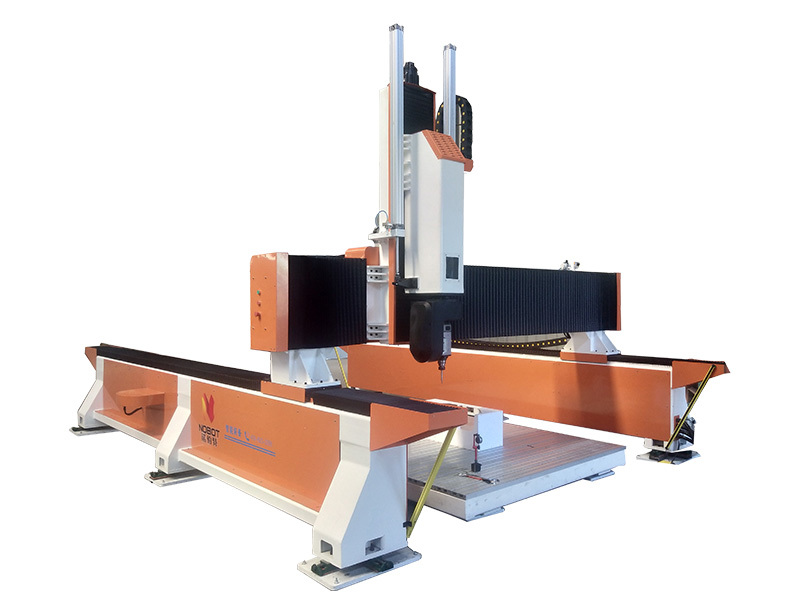

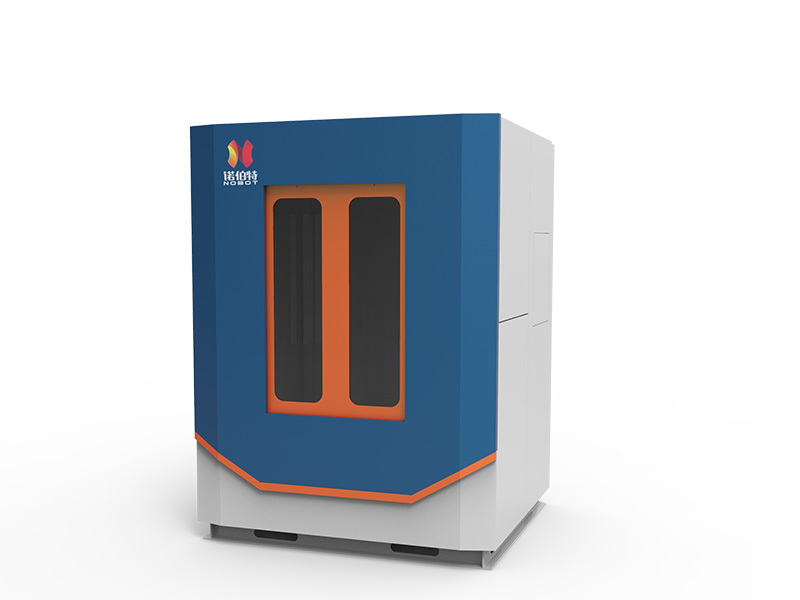

NBFS series five-axis machining center for real wood and aluminum car interior

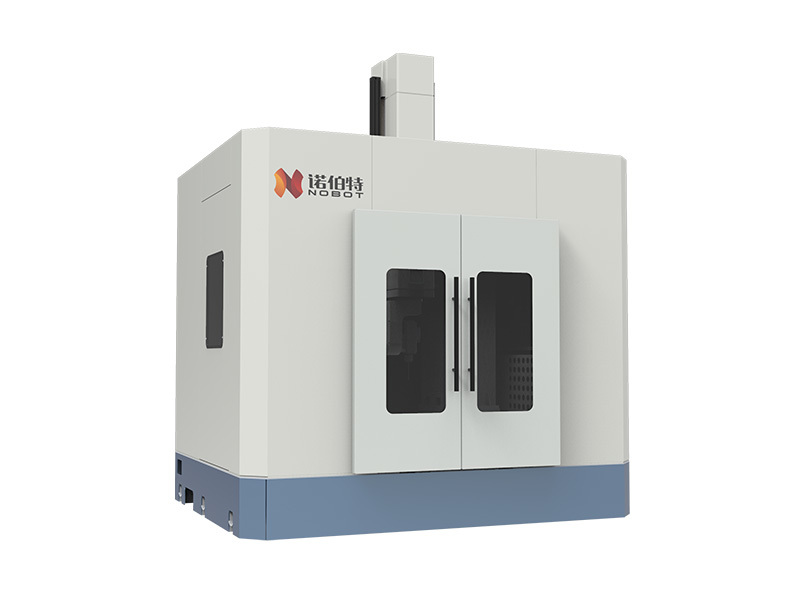

Double-rotary table horizontal five-axis machining center

Small and medium-sized casting grinding and deburring equipment

Small and medium-sized casting grinding and deburring equipment

Small and medium-sized casting grinding and deburring equipment