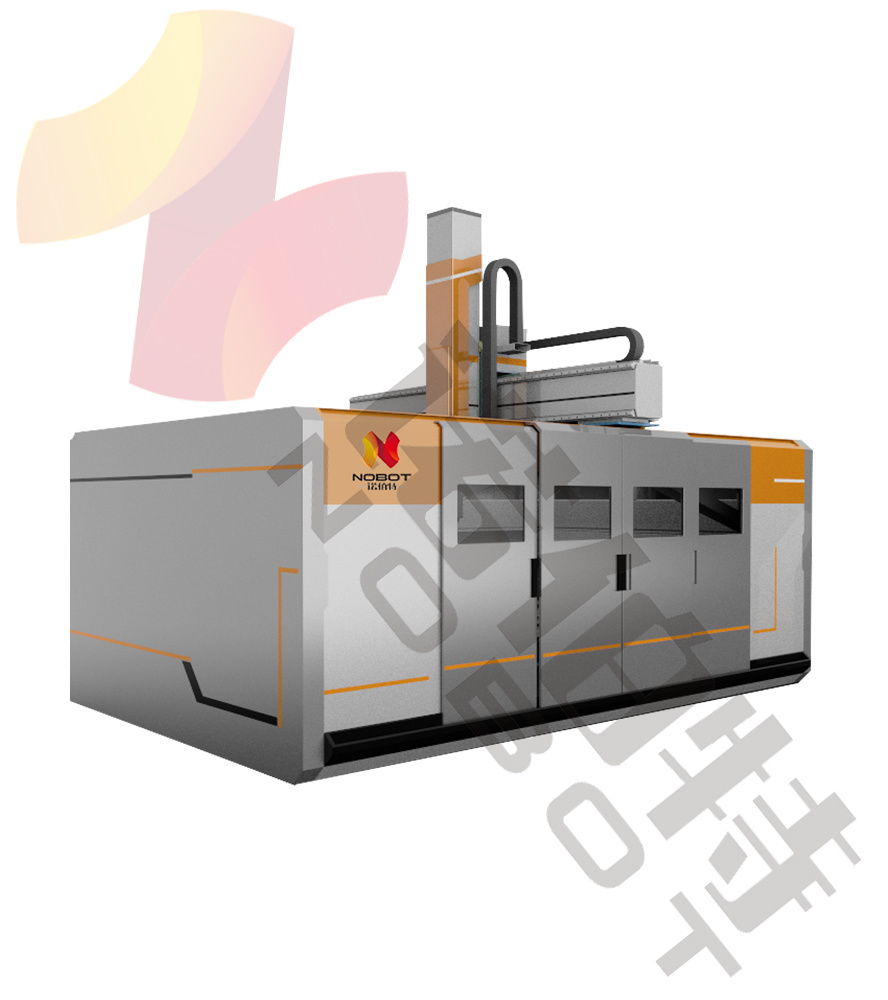

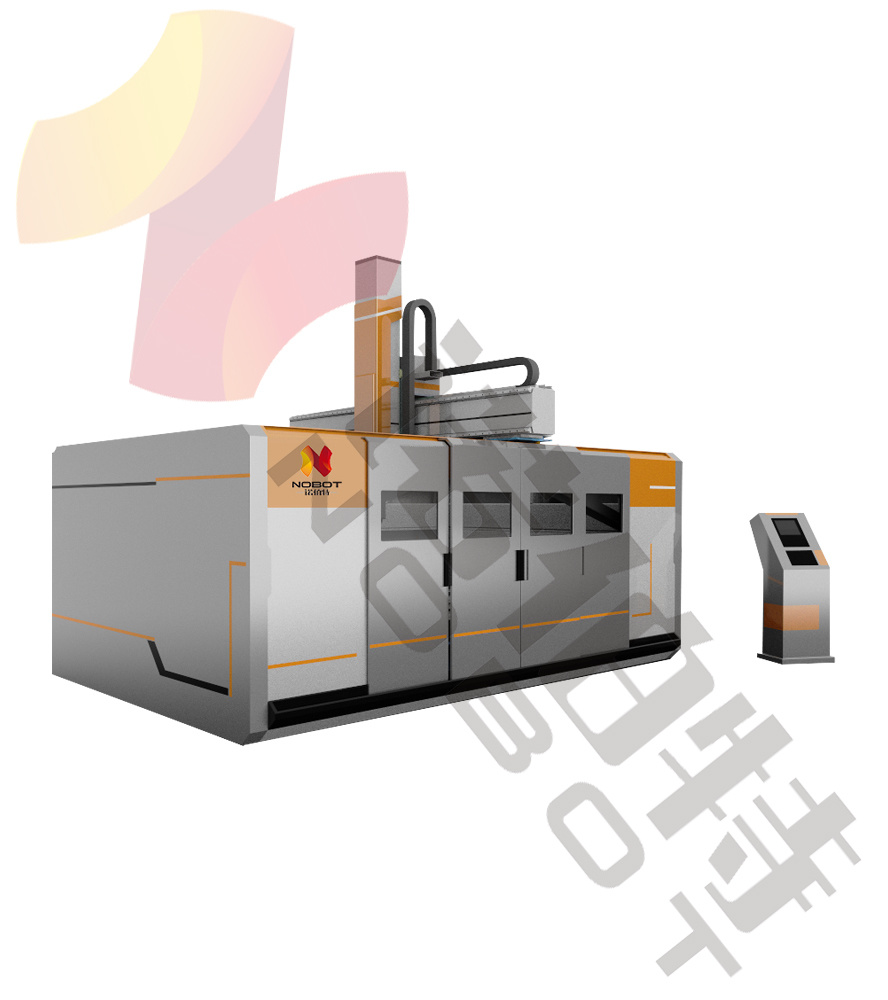

QF series composite five-axis machining center

This product uses a gantry-style protective cover with a fully enclosed structure, effectively preventing the random splashing of chips and improving equipment safety.

Keywords:

Details Description

I. General Introduction

The QF series five-axis machining center adopts an advanced gantry-type mobile structure, possessing the excellent cutting characteristics of a high-speed milling machine. The mobile worktable ensures the machine tool has optimal dynamic motion characteristics and drive rigidity. The worktable moves smoothly in the axial direction. During processing, the five axes drive the tool movement, machining around the workpiece to achieve five-axis linkage three-dimensional movement. The dual worktable allows for uninterrupted production processing, with one worktable being machined while the other is loaded.

II. Equipment Structure

X-axis: Horizontal movement of the gantry slider (tool)

Y-axis: Front and rear movement of the table support

Z-axis: Vertical movement of the gantry slider (tool)

C-axis: Rotational movement of the tool along the Z-axis

A-axis: Relative angle movement of the tool with respect to the Z-axis, completing inclined surface machining.

III. Product Features

1. Equipped with 35# heavy-duty guide rails and flange sliders, large-modulus high-precision gear racks, large cutting force, stable transmission Stable, high precision.

2. Equipped with an Italian imported electric spindle, with a maximum power of 17KW, output torque up to 10N.M, maximum speed up to 24000 rpm, meeting the requirements of high-speed cutting.

3. Adopts a thick steel plate worktable and bed body integrated welding, after two stress relief annealing, effectively ensuring the cutting rigidity and stability of the machine tool, achieving long-term use without deformation.

4. Uses a Japanese-made Sumitomo RV high-rigidity, high-torque reducer as the core component of the fourth axis, effectively ensuring the stability of the B-axis during high-torque cutting.

5. Can be equipped with a servo automatic tool changer, with a tool magazine capacity of 8 tools, allowing for the installation of various tools at once, with fast tool changing speed.

6. Adopts a gantry-type protective cover, with a fully enclosed structure, effectively preventing the random splashing of chips and improving equipment safety performance.

7. Equipped with a dedicated oil mist lubrication system, no cutting waste liquid is produced, protecting the environment and reducing energy consumption.

8. Equipped with a chip collector to help workers quickly clean the machine tool.

9. Complete isolation between personnel and the processing area, better safety, dust cover noise reduction.

IV. Application Range

V. Technical Specifications

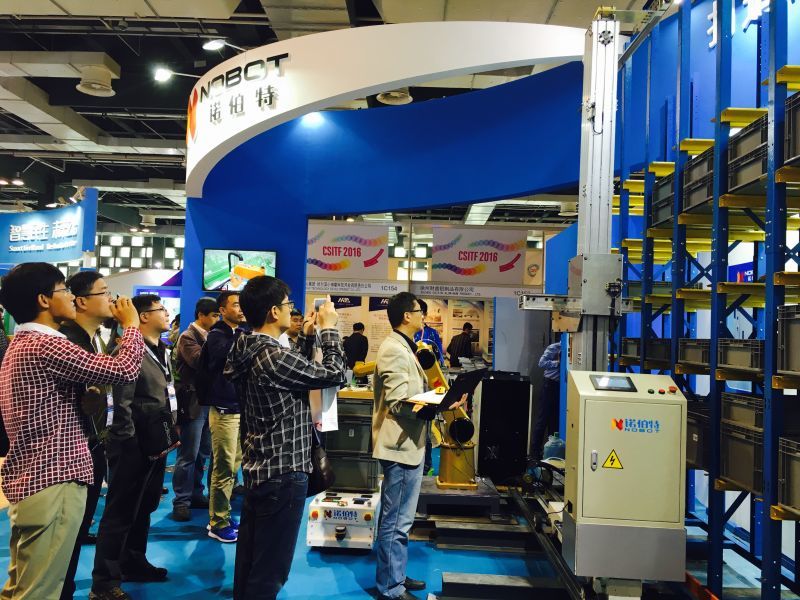

Nobot's five-axis machine division focuses on the research and development of advanced domestic five-axis machining centers, providing one-stop solutions for the CNC machining of materials such as aerospace, rail transit, new energy vehicles, and composite materials.

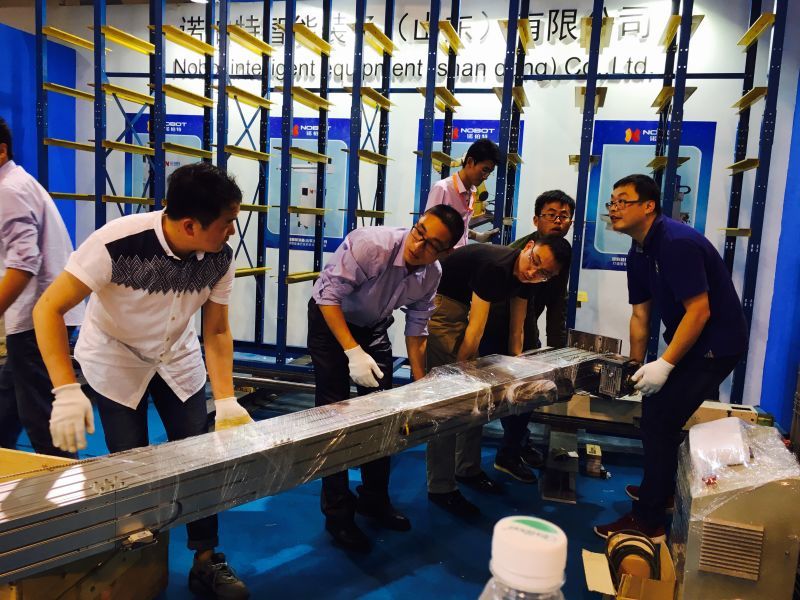

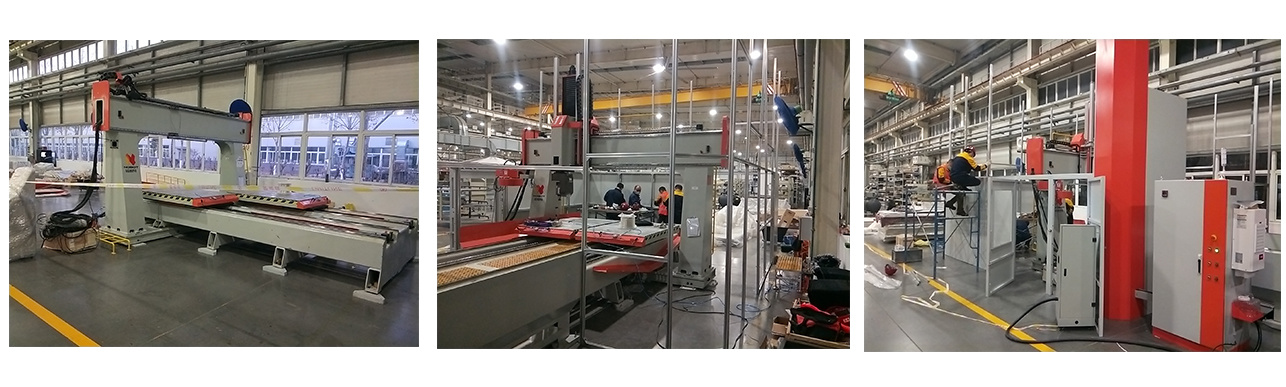

VI. Construction Site

VII. Enclosed Five-Axis Engraving Machine Cutting Video

For more videos, please follow Nobot's official Douyin account: nobot

Application Cases

Nobot (NOBOT) is committed to intelligent equipment solutions

Get a quote

We are always here to help! Please fill out our inquiry form and our team will reply promptly.

Nobot Production Capacity

Nobot (NOBOT) is committed to intelligent equipment solutions

Manufacturing Capacity

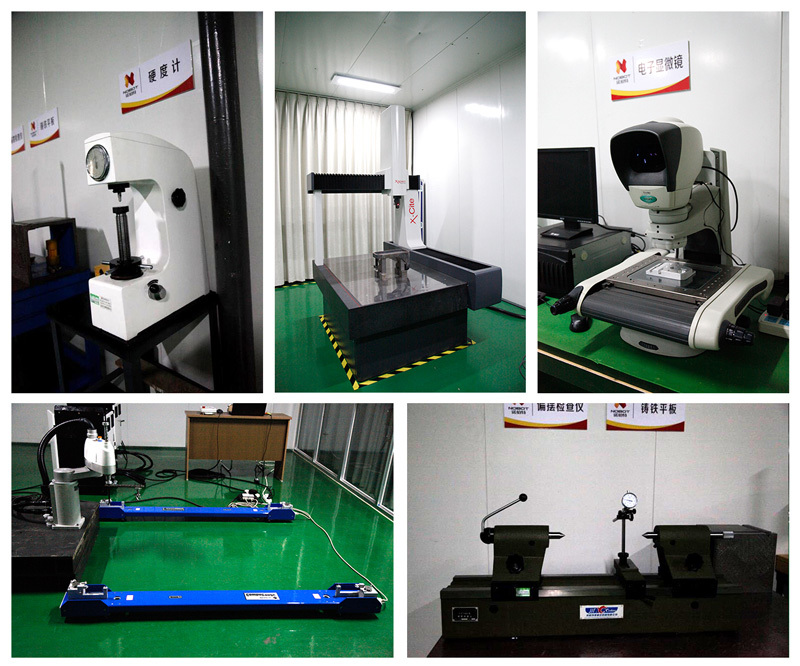

Detection Capacity

Equipment Advantages

Recommended Products

Nobot (NOBOT) is committed to intelligent equipment solutions

DQF series fully enclosed high-speed five-axis gantry machining center

NBF series general-purpose five-axis machining center

NBFS series five-axis machining center for real wood and aluminum car interior

Double-rotary table horizontal five-axis machining center