ABB robot IRB 660

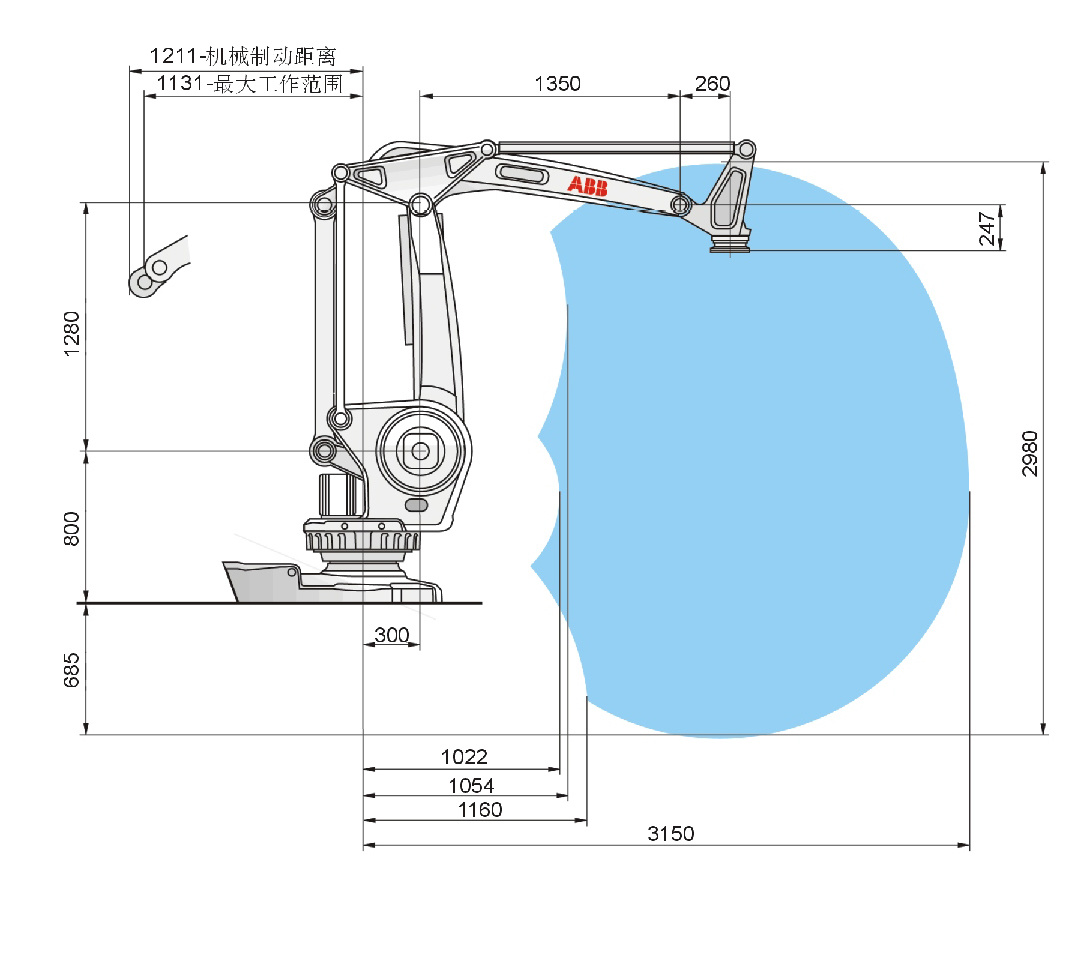

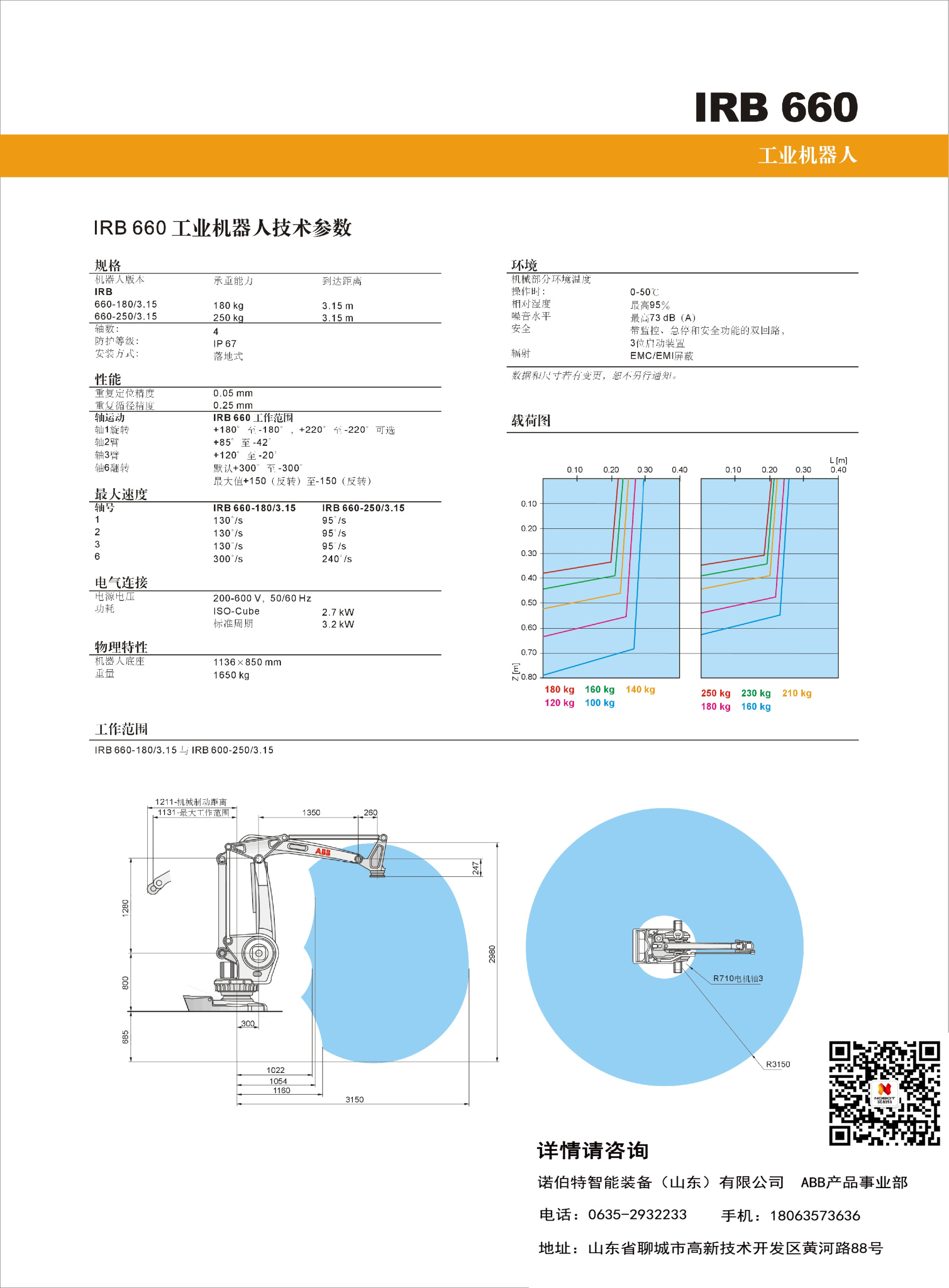

The ABB IRB 660 is a dedicated palletizing robot that stands out in its class for speed, reach, and payload. Its ultra-high-speed 4-axis mechanism, 3.15-meter reach, and 250KG payload make the ABB IRB 660 ideal for palletizing bags, boxes, bottles, crates, and other packaging materials.

Details Description

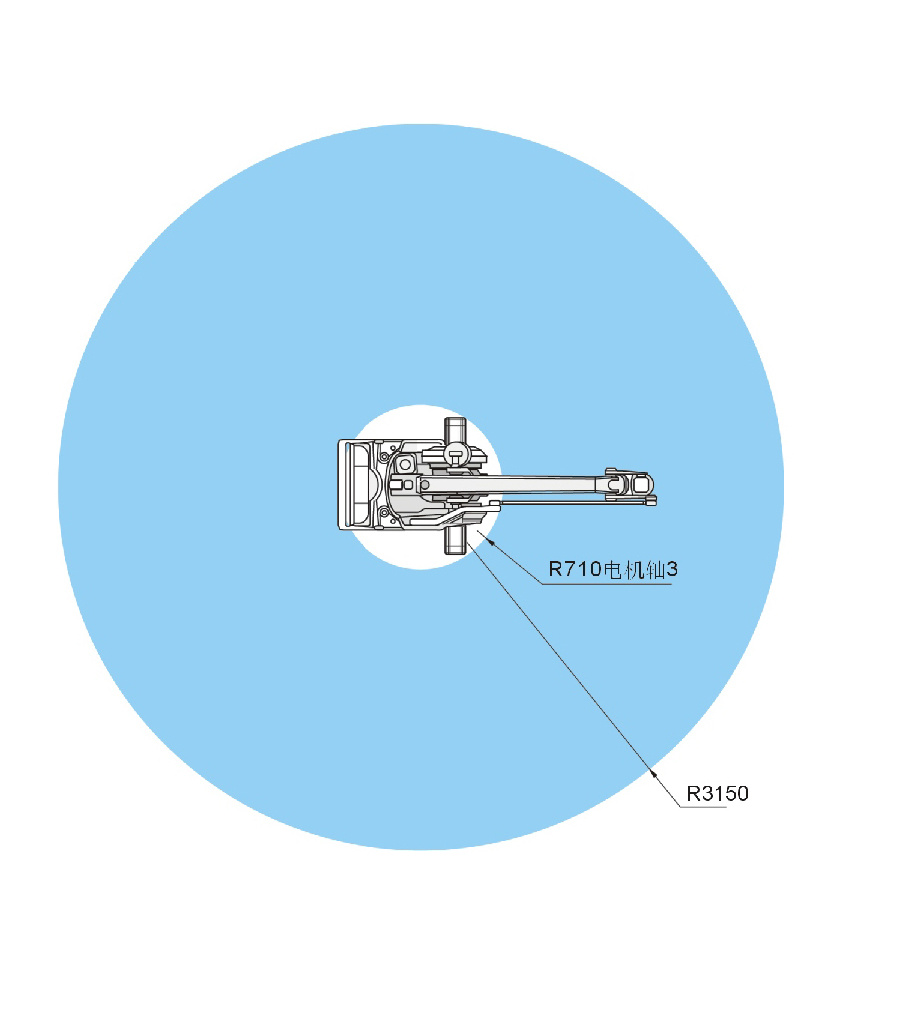

The ABB IRB 660 is a dedicated stacking robot that stands out in its class for speed, reach, and payload. Its ultra-high-speed 4-axis mechanism, 3.15-meter reach, and 250KG payload make the ABB IRB660 ideal for stacking bags, boxes, bottles, and crates. The IRB660's operating speed is significantly improved over its predecessor. Optimized motor power and motion performance result in significantly shorter cycle times than competing products. This new stacking robot comes in two versions: a high-speed version and a 250KG version. The former can handle a 180KG payload at full speed, while the latter enables high-throughput operation. The IRB660 boasts an exceptional reach, capable of simultaneously handling four infeed conveyors, two pallet stacks, one slip sheet stack, and four stacking output lines at full load.

Application Cases

Nobot (NOBOT) is committed to intelligent equipment solutions

Get a quote

We are always here to help! Please fill out our inquiry form and our team will reply promptly.

Nobot Production Capacity

Nobot (NOBOT) is committed to intelligent equipment solutions

Manufacturing Capacity

Detection Capacity

Equipment Advantages

Recommended Products

Nobot (NOBOT) is committed to intelligent equipment solutions

DQF series fully enclosed high-speed five-axis gantry machining center

NBF series general-purpose five-axis machining center

NBFS series five-axis machining center for real wood and aluminum car interior

Double-rotary table horizontal five-axis machining center