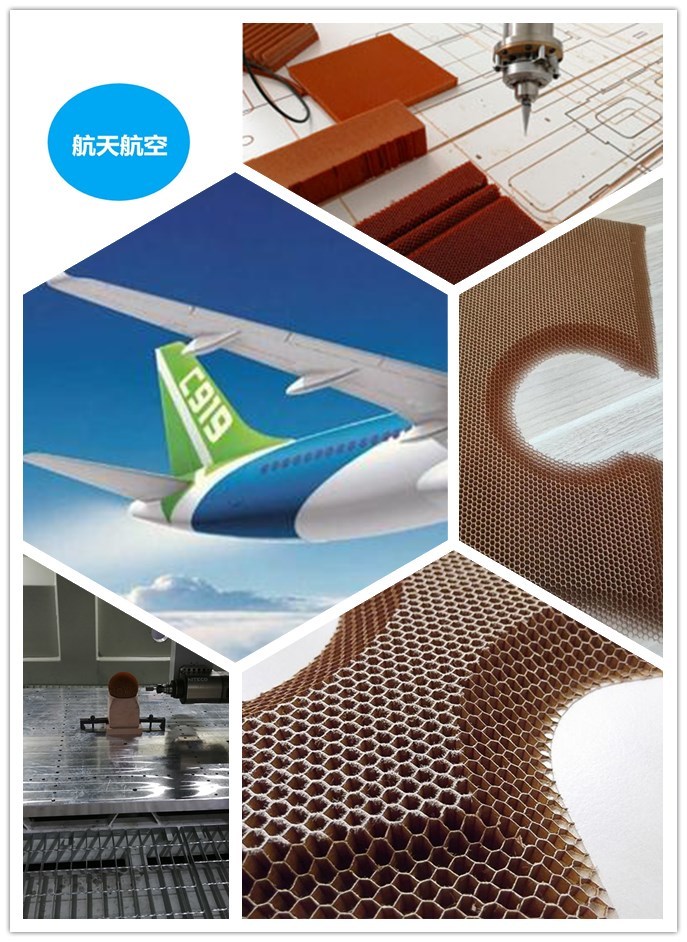

Honeycomb material is a composite material, commonly referred to as honeycomb structure in the aerospace field. In the aerospace industry, honeycomb sandwich structures are often used to manufacture various panels, wings, cabin surfaces, hatches, floors, engine shrouds, nozzles, silencers, heat shields, and satellite bodies.

Feb 23,2018

Nobot industrial robots promote China's Industry 4.0

In March, Premier Li Keqiang proposed the "Internet Plus" action plan in the Government Work Report to promote the integration of mobile internet, cloud computing, big data, and the Internet of Things with modern manufacturing. The simultaneously released "Made in China 2025" plan focuses on intelligent manufacturing. This indicates that China's manufacturing industry has sounded the call for Industry 4.0.

Feb 23,2018

Lead ingot stacking production line scheme

At the client's request, improvements and upgrades are needed for the client's factory workshop. Specifically: 1. Improve the company's automation level and accelerate production efficiency; 2. Reduce redundant personnel and increase company revenue; 3. Reduce labor risks and maximize safety in production. Process: 1. Products are completely demolded by the casting machine through a vibration device; 2. After demolding, they are placed on the conveyor belt via a receiving device; 3. The conveyor belt transports the workpiece to the deburring station, where the deburring device performs positioning and deburring, powered by an oil cylinder; 4. Deburring...

Feb 05,2018

The unstoppable rise of press robots

Handling, sorting, palletizing, grinding, polishing, cutting, welding, spraying, assembling... Industrial robots can do almost anything. Theoretically, they can do anything as long as the appropriate end-effector is connected to the end of the general-purpose robot and the correct program is written into the control box. From Foxconn, a "contract manufacturing empire" with nearly 100,000 employees, to small start-ups with only a few people, industrial robots have quietly entered the production lines of more and more Chinese manufacturing enterprises. Pressing robot. Data shows that China is one of the countries with the highest growth rate in robot demand. Companies such as Fanuc from Japan and KUKA from Germany have robots in China.

Feb 05,2018

Electronic automatic sorting system

1. Project Introduction: The FPC loading machine is a high-precision device developed by our company for a large listed company, used for quickly picking and accurately placing FPCs. 2. Project Characteristics: The device mainly consists of a parallel robot, vision components, industrial computer, controller, and conveyor belt. Based on high-performance and high-precision parallel robots and visual processing, the device is more convenient and efficient for applications in electronics, food, and medicine industries. The device achieves an efficiency of up to 4800 units/hour in the FPC loading process, greatly saving manpower and improving efficiency. 3. Project Plan Serial Number Set

Feb 05,2018

Press robot loading and unloading project

1. Project Introduction: Three small four-axis machines are used for processing non-metallic materials. 2. Project Characteristics (1) The NF4-2312-F non-metallic processing center is a four-axis processing center specially designed for reprocessing non-metallic products in bags, independently developed and produced by Nobot Intelligent Equipment (Shandong) Co., Ltd. (2) This machine has powerful processing capabilities and is not limited by the shape of the product. It can perform any shape of cutting and punching operations on any surface of the product to be processed. (3) This machine departs from traditional programming and adopts a simple and easy-to-learn programming mode. (4) This machine...

Feb 05,2018

Advantages of Automated Delivery Intelligent Automated Warehouses

(1) All warehousing operations in automated delivery intelligent automated warehouses are fully automated, reducing a large amount of labor costs. At the same time, the reduction in labor costs can greatly reduce errors caused by human factors.

(2) Traditional warehouses use horizontal shelves, wasting a large amount of warehouse space resources. Automated delivery intelligent automated warehouses use a high-level shelf design, effectively utilizing the vertical space resources of the warehouse and reducing the horizontal area utilization rate.

(3) Automated delivery intelligent automated warehouses

Feb 01,2018

ABB industrial robots and Nobot have reached a gold partnership

ABB industrial robots have been dedicated to the research and development and production of robots for over 40 years, with over 200,000 robots installed globally. ABB industrial robots are pioneers and a world-leading manufacturer of industrial robots, with research, manufacturing, and sales bases in Sweden, Norway, and China. ABB industrial robots sold the world's first painting robot in 1969, followed by the world's first industrial electric robot in 1974. They possess the widest range and most comprehensive selection of robot products, technologies, and services available today.

Jan 22,2018