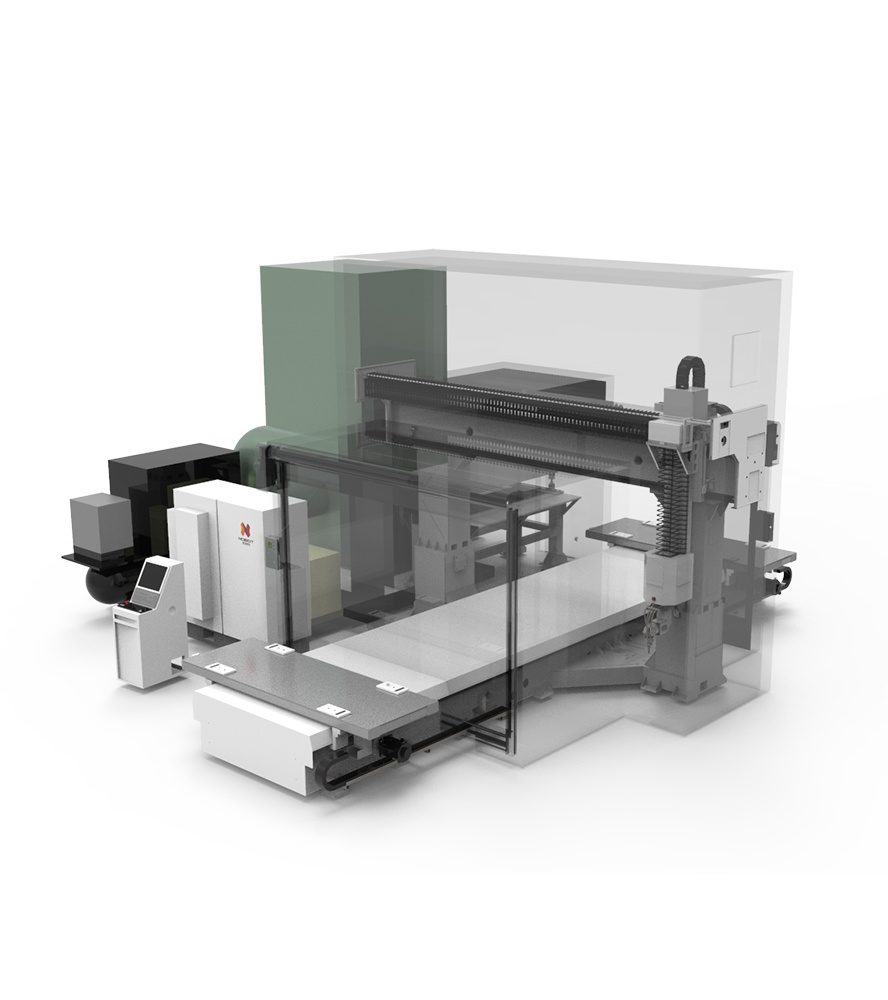

Three-dimensional five-axis laser processing center

The three-dimensional five-axis laser cutting system is a series of high-performance products developed by our company based on market demand and aimed at the subsequent processing of automotive interior and exterior parts, new energy battery boxes, cruise ship and submarine interior parts, bathroom supplies, and other industries.

Details Description

1. Product Introduction

The three-dimensional five-axis laser cutting system is a series of high-performance products developed by our company based on market demand and aimed at the subsequent processing of automotive interior and exterior parts, new energy battery boxes, cruise ship and submarine interior parts, sanitary ware, and other industries. This series of products adopts an overall gantry structure, which can achieve the processing of ultra-large workpieces, and the addition of an automatic feeding platform can achieve simultaneous processing and feeding. The system is equipped with a high-power carbon dioxide laser, which introduces laser energy into the precision cutting head through a lens system. The control system precisely controls the movement trajectory of the XYZAC axes to achieve three-dimensional stereoscopic cutting. It is a high-end machine tool equipment integrating optics, mechanics, electricity, and pneumatics.

2. Product Features

(1) Motion Characteristics: Five-axis linkage three-dimensional processing

When processing three-dimensional five-axis laser cutting workpieces, the five axes drive the tool movement simultaneously, and the tool processes around the workpiece, realizing five-axis linkage three-dimensional movement.

(2) Processing Objects : Non-metallic workpieces

ABS, SMC, glass fiber, carbon fiber, and other non-metallic composite materials are widely used in automotive interior parts, new energy battery boxes, cruise ship and submarine interior parts, sanitary ware, and other industries.

(3) Structural Characteristics : FEA analysis + instrument verification

The main structure of the machine tool is designed using FEA analysis. The bed and ground rails are welded from high-quality steel profiles and plates; the crossbeam and slide are made of aviation aluminum castings; the main body has undergone special aging treatment, and the moving parts have undergone simulated static and dynamic load verification, improving the stability of the machine tool while increasing its dynamic performance.

(4) System Features : System stability + convenient operation

It adopts a Japanese imported FANUC five-axis numerical control system. It can be taught and offline programmed, and the operation is simple and convenient. RTCP is opened, with five-axis linkage and tool tip compensation functions. Equipped with offline programming software, it can perfectly process complex 3D contours.

(5) Constant Optical Path Design : Optical path compensation axis

The laser generator output port is designed with a collimating mirror, and the optical path is parallel light. Through the optical path compensation axis, it prevents changes in the focal point due to changes in the optical path length.

3. Product Advantages

Cost reduction and efficiency increase (From the customer's perspective)

(1) Cost reduction :Using FANUC laser generator ,high stability, continuous operation for 8 hours, ±1% deviation; gas consumption is about 10L/h (shown in the laser parameter table below), the laser runs continuously for 24 hours, and the monthly gas consumption is 7.2 cubic meters, which costs 2850 yuan, saving more than 50% gas compared to a certain domestic brand laser.

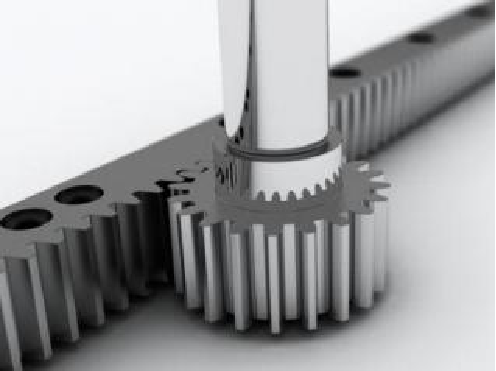

(2) Efficiency increase :The gantry adopts dual-motor drive, the equipment has high body rigidity and good stability, the cutting speed reaches 2.5m/min, and the cutting efficiency is increased by about 15% compared to a certain domestic brand laser cutting machine, and the thickness of the carbonized layer after cutting is 0.03~0.1mm.

|

Serial Number |

Laser Generator Brand |

Gas Consumption |

Remarks |

|

1 |

ROFIN, Germany |

Less |

Imported |

|

2 |

Japan FANUC |

Less |

Imported |

|

3 |

Japan Panasonic |

General |

Imported |

|

4 |

Japan Mitsubishi |

General |

Imported |

|

5 |

Precitec |

Higher |

Domestic |

4. Core Components

(1) Welded bed, ground rail, cast crossbeam, slide

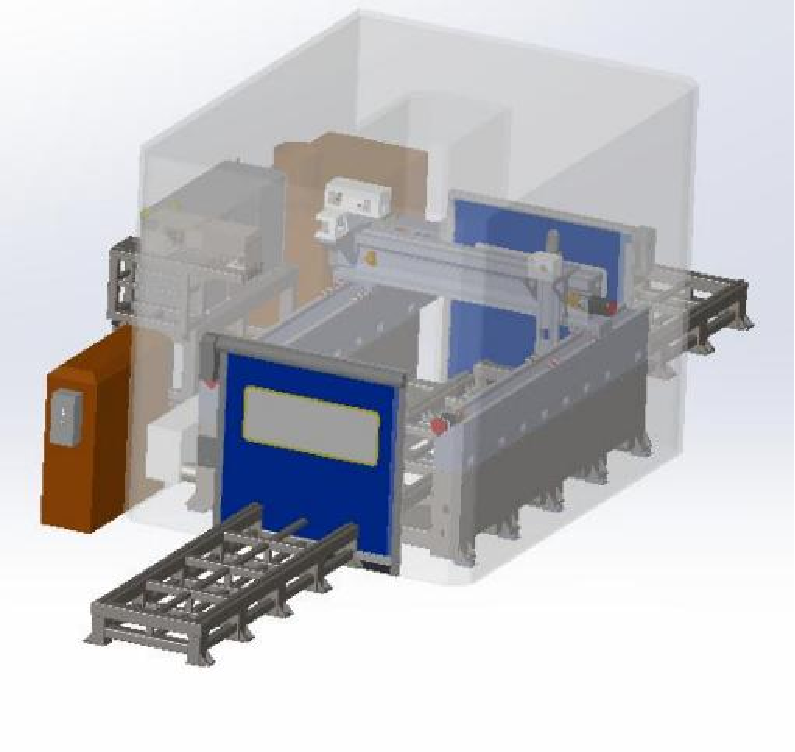

This product uses a gantry machine tool body: the moving beam crossbeam, and the three-station worktable move horizontally along the ground rail. It can realize one-in-one-out work of the worktable, increasing work efficiency. Through simulation analysis of the static and moving parts, the movement efficiency is improved, and the maximum speed of the X, Y, and Z axes of the equipment reaches 60m/min.

• The bed and ground rails are welded from high-quality steel profiles and plates, improving the equipment's rigidity.

• The crossbeam and slide are made of aviation aluminum castings, reducing the weight of the moving parts and improving the equipment's dynamic performance.

(2) FANUC five-axis numerical control system

Highlight 1: Complete solution for laser five-axis cutting

For laser cutting applications, Xinde integrates motion control, laser control, cutting technology, and human-machine interface elements. Xinde provides a packaged electrical control solution, allowing users to easily meet the needs of laser cutting applications without the need for additional customized development.

Highlight 2: Cutting-specific process package

The controller has built-in laser cutting-related processes, providing speed-power curves, multi-level piercing, and follow-up control (docking with other regulators, Jiaqiang, Baichu, etc.) functions, which can achieve good cutting processing effects.

Highlight 3: Low application threshold

Provides a conversational teaching interface design, intuitive user experience, and users can easily complete the cutting process teaching without additional learning of G-code programming.

Highlight 4: Supports advanced five-axis cutting technology

RTCP: For five-axis cutting applications, it provides RTCP surface speed control. For five-axis simultaneous motion applications, it accurately controls the speed at which the laser focal point moves on the workpiece surface.

3D Software Programming: The controller can recognize standard G/M codes, interface with commercially available 3D software, provide reliable and accurate cutting paths, and achieve complex surface processing.

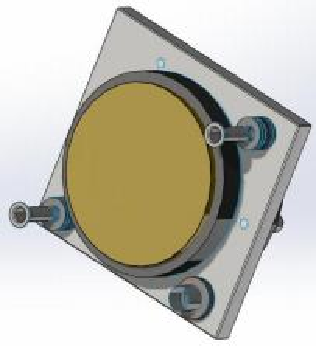

(3) Three-dimensional five-axis cutting head

• High reliability: Passed a long-term 24h continuous operation test.

• High-speed cutting: Tests verify that it achieves the cutting speed of imported equipment, with a C/A axis rotation speed of 120r/min. • High precision: Using direct drive, high precision, wear-free, C/A axis rotation repeatability <0.005°. • User-friendly design: The cutting nozzle uses a slender design, fully considering product cutting interference, and can achieve processing of most three-dimensional workpieces on the market.

• Convenient maintenance: Using a modular design, making it easy to replace wearing parts and reducing maintenance costs.

• Control system: Uses internationally common communication protocols, perfectly integrates with the control system, and realizes five-axis linkage function (RTCP).

• Optical system: Precision optical structure design, when five-axis linkage, any focal point change value ≤ ±0.05mm, ensuring cutting quality at various angles.

• Collision prevention function: Equipped with 360-degree side collision prevention and disengagement protection.

• Intelligent detection and protection: Equipped with temperature sensors, water immersion sensors, gas pressure sensors, collision disengagement sensors, and other detection feedback systems.

• Special structure: Adopts an integrated design of electricity, water, gas, and laser, which can realize 360° unlimited rotation of the C-axis and ±135° rotation of the A-axis.

(4) Other key components

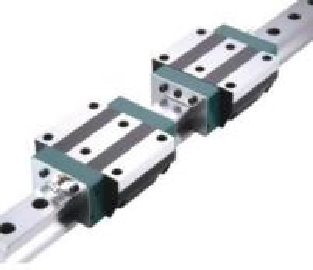

Taiwan TBI/HIWIN United States 26 (lens) Taiwan APEX

Japan FANUC servo + system Taiwan APEX Bosch Rexroth/Taiwan TBI/HIWIN

5. Key Technical Indicators

| Model | NL0101-DS3018 |

| Laser type | Carbon dioxide (wavelength 10.6μm) |

| Laser power | 1000W/2000W/4000W/6000W (power size selectable according to cutting material) |

| Laser brand | FANUC/NOBOT |

| Structure type | Gantry type |

| Worktable | Dual station |

| Worktable load capacity | 800KG |

| Laser cutting head | Single |

| Processing range | 3000×1800×600 |

| Positioning accuracy | ±0.05mm |

| Cutting speed | Up to 20m/min (depending on material and thickness) |

| Repeat positioning accuracy | ±0.03mm |

| Servo and driver | FANUC/Yaskawa |

| Control system | FANUC/NOBOT |

| Programming method | Offline programming + teaching programming |

| Floor space | 8500x8000x4500mm |

Application Cases

Nobot (NOBOT) is committed to intelligent equipment solutions

Get a quote

We are always here to help! Please fill out our inquiry form and our team will reply promptly.

Nobot Production Capacity

Nobot (NOBOT) is committed to intelligent equipment solutions

Manufacturing Capacity

Detection Capacity

Equipment Advantages

Recommended Products

Nobot (NOBOT) is committed to intelligent equipment solutions

DQF series fully enclosed high-speed five-axis gantry machining center

NBF series general-purpose five-axis machining center

NBFS series five-axis machining center for real wood and aluminum car interior

Double-rotary table horizontal five-axis machining center