-

-

-

Application

-

-

-

-

Service

Application

Contact Us

Pre-sales consultation:86-635-2932233

Fax:86-635-2945333

After-sales consultation:86-635-5086881 / 86-635-2936881

National unified service hotline:86-400-823-3356

Email: nuobote@nobot.cc

WhatsApp: 85244839434

Address: No. 1 Factory, Huanghe Road, No. 88, High-tech Zone, Liaocheng City, Shandong Province

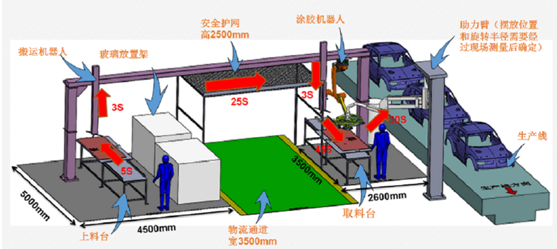

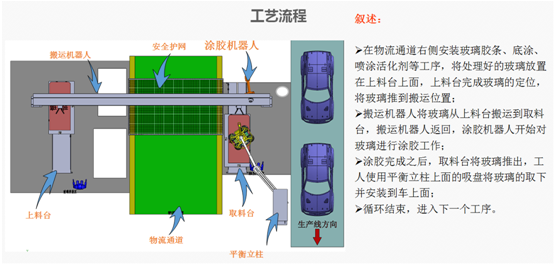

Automotive glass coating robot system

In the automotive manufacturing industry, adhesive robots are widely used and in demand. Nobot Intelligent Equipment (Shandong) Co., Ltd. has developed a glass robot dispensing system based on market needs. The system features high automation, high efficiency, and stable quality, and is widely used in major automobile factories.

Nobot Intelligent Equipment Group Co., Ltd.

Pre-sales consultation:86-635-2932233

Fax:86-635-2945333

After-sales consultation:86-635-5086881 / 86-635-2936881

National unified service hotline:86-400-823-3356

Email:nuobote@nobot.cc

Address: No. 1 Plant, No. 88 Huanghe Road, Gaoxin District, Liaocheng City, Shandong Province

copyright © 2025 Nobot Intelligent Equipment Group Co., Ltd.